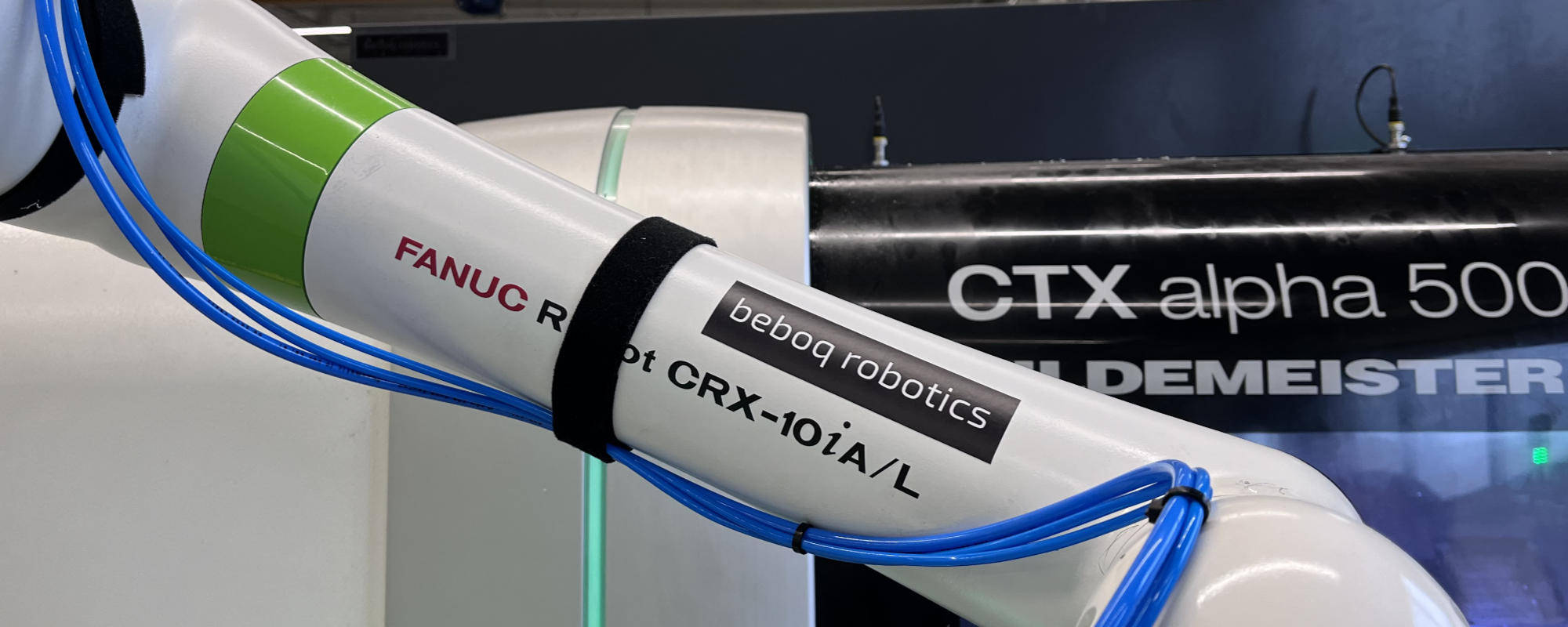

PDCP robotic machine loader is a complete workstation for machines such as mills, lathes, CNC, presses and others. CNC machine tending station by beboq robotics is based on reliable Fanuc CRX high repeatability collaborative robots. Our collaborative machine tending station can be customized for any machining center manufacturer and combine many auxiliary functions. They are fast and easy to program, meet all safety requirements and provide a short return on investment.

One of the primary applications of collaborative robots is to use them as operators of machines – CNC milling and turning machines, presses, or other equipment. The role of a collaborative robot is to replace a human in the repetitive process of placing the workpiece in the machine, running the machining cycle and picking up the processed workpiece. The existing machine operator, in this case, can be freed up for more demanding tasks, including controlling the machining process.

What stands out about PDCP robotic CNC machine tending stations

- Easy to use and intuitive operator panel

- Can be programmed to handle a workpiece in as little as 15 minutes

- Can operate both lathes and milling machines

- Ability to use a dual gripper for faster changeover cycles

- Can be integrated with an additional measuring machine that transmits corrections to the machine tool

- Vise / lathe chuck blow-off on robot flange

- Optional additional blowdown inside the machine

- Workpiece centering in the lathe chuck

- Chip detection in vise / lathe chuck

- Automatic detection of the bottom of the vise / chuck

- Interacts with workpiece storage for maintenance-free operation

- Large robotic payload capacity

- Machine tool door automation for increased safety and process speed

- Workstation design for easy access to CNC machine tool workspace

- Ideal for diversified production

- Always compliant with ISO 15066 technical standard, CE declaration and full documentation

- Solves the shortage of operators on the market

- Crew training and after-sales care

- Fast return on investment time (ROI)

You can read about preparing for robotic machining in our article: Is your company ready for machining automation?

Beboq Robotics offers robotization stations for CNC machines from brands including Haas, Fanuc, Mazak, Doosan, Okuma, DMG Mori and many others. The set includes: a Fanuc CRX collaborative robot, a single or double gripper, a robot station with a raster table or drawer workpiece magazine, full pneumatic and electrical installation, and an electrical kit for integration into the machine tool. In addition, the set can be complemented with an automatic vise and a system for safe automatic opening and closing of the machine tool door.

We offer probably the most cost-effective CNC machine tending stations on the market.

Not just a cobot. The most important features of our machine loader for CNC and other machines

The basics of automation

Robotization of CNC mills and latches (but also other) requires integration at the level of: cycle start, i.e. the robot starts the work cycle, the robot waits for the cycle completion signal, proper integration of safety systems, robot-managed closing and opening of the machine door and robot-managed opening and closing of the workpiece fixture in the machine, e.g. by automating the vise in the milling machine or the lathe chuck, as well as the signal of its proper closing.

The application can be expanded to include automatic measuring devices such as Renishaw, Keyance, Mitutoyo, Keyence or others. Then each or every predetermined workpiece can be subjected to measurements, e.g. of dimensions, and the measuring machine will automatically feed the necessary corrections to the machining center.

Intelligent and adaptive grippers

What makes the workstation universal (besides the collaborative robot) are grippers – adjustable, easily rearmed mechanically or controlled by software (force, speed, feed, finger spacing), with a wide range of parameters, with interchangeable finger shapes, good IP. So as to maximize the time required to prepare the station for a new task and reduce the cost of production handling.

To reduce the time for changing workpieces in the machine, you can use a double gripper, where each is separately managed by a cobot. In such an arrangement, one gripper retrieves the workpiece from the machine, while the other places a fresh object for processing. Such a machine reload cycle is typically 40% faster than with a single gripper.

Workstations, racks and conveyors

Racks with drawers can be used for picking and putting away workpieces, instead of a standard raster table. Due to their total surface area, they can provide a larger capacity of workpieces than a single table, or physically separate the worker from the robotic station. The workstation can also be supplied with workpieces via a conveyor-belt, which the robot can manage.

Accessibility

Constant access to the workspace of a CNC milling or turning machine is very important. Whether it’s because the workstation can be easily programmed, the machine tool serviced, workpieces measured during operation, or individual pieces can be made without the robot. Therefore, all of our workstations are built with this in mind – to allow easy access.

Gallery of collaborative machine tending stations